Innovation for future railway maintenance

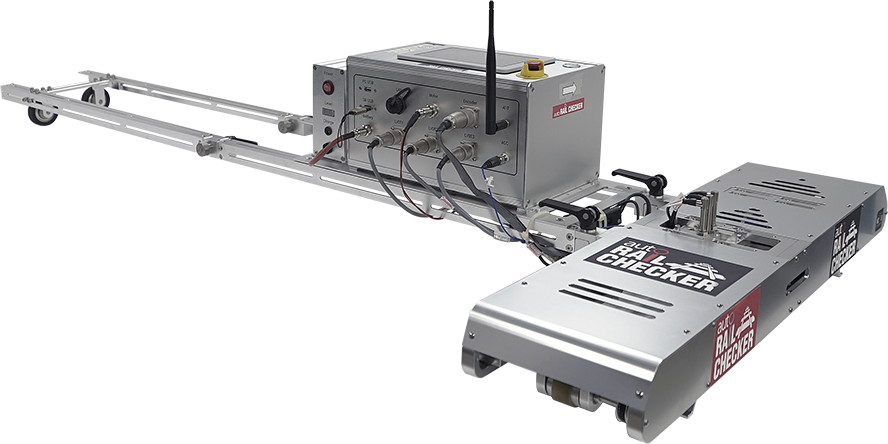

auto RAILCHECKER is the solution to check the unevenness of the rail surface and it is such an innovative solution because it can not only guarantee your safety for work but also save your time. The applied technologies have been supported by Korea Railroad Research Institute and R&D project of Korea Ministry of Land, Infrastructure and Transport.

How?

auto RAILCHECKER has 3 displacement sensors and 1 acceleration sensor.

Each measured raw data is calculated with our own algorithm and user can see the roughness values.

Each roughness value can also be calculated into frequency and then user can compare that result to ISO3095 and well as decide when to grind the rail.Because of the high technology of the sensor, rail corrugation can also be detected by auto RAILCHECKER.

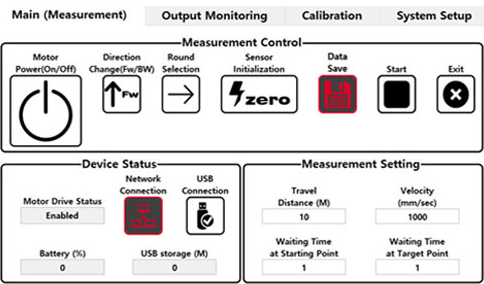

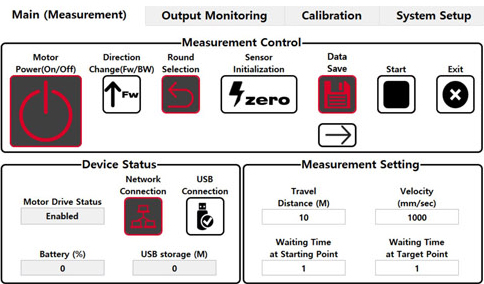

OperationEasy operation of auto RAILCHECKER is truly outstanding. auto RAILCHECKER is running automatically as you set the distance (Max. 2 Km) and it comes back to the point where it started. |

|

|

|

|

|

|

|

|

|

Modern railway technologies provide us fast and comfortable transportation every day. As the technology progresses, our journey is now more safe and convenient but also there are some drawbacks we should bear.

One critical drawback is the rolling noise from the train especially in the city/ urban areas. Reducing rolling noise is one of the key steps for next progress of railway technology.

For example, rolling noise in metro railway applications (average speed of 50~80 Km/h), is largely associated with various rail and wheel contact conditions. Therefore, assessing roughness of rail and wheel is the key to preventing harsh rolling noise.

InnovativeUnlike other conventional solutions, auto RAILCHECKER provides

|

|

Fasterauto RAILCHECKER runs with an internal motor. It can cover more area than conventional manual devices. You can check more area in same time and can finish your jobs within less time. |

SafeAn Operator can stand away from the tracks during the entire operation so unexpected accidents are unlikely. |

Accurate/ ReliableMultiple types of sensors measure the rail’s roughness simultaneously and the internal algorithm always guarantees the best results. |

Convenienceauto Rail Checker operates autonomously so the only thing the operator needs to do is to check remotely whether the device is running properly and download the data once the operation is completed. There is no need of laborious push and walk with the device as other conventional solutions. |

|

Auto RailChecker : An Innovative Measuring System of Rail Roughness

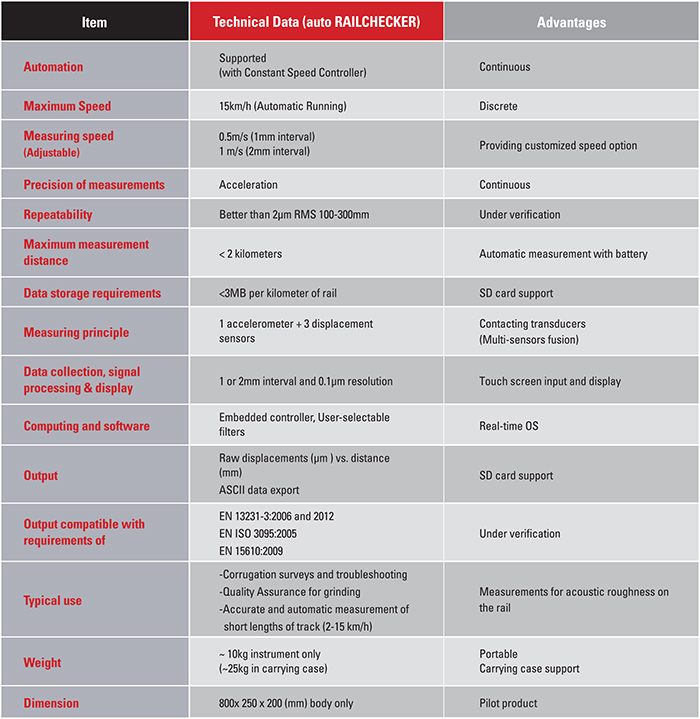

autoRailChecker Specifications